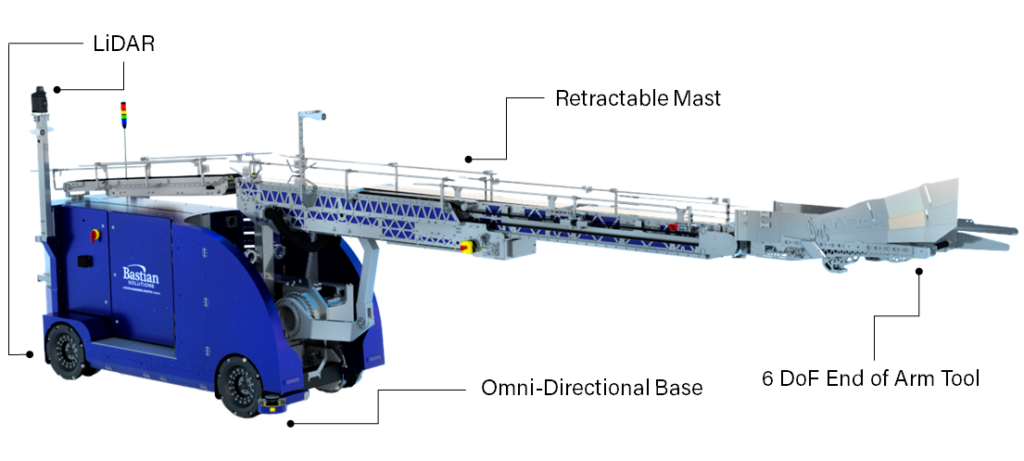

Bastian Solutions’ ULTRA BLUE robot reaches into a trailer. Source: igus

Robotic systems deployed in warehousing environments often face demanding conditions, such as temperature fluctuations, the presence of dust, and constant high-impact loads. Traditional metal machine components — particularly bearings that rely on external lubrication — are vulnerable in these environments, leading to more frequent maintenance, downtime and potential contamination issues.

Bastian Solutions, a material handling system integrator, ran into many of these issues when designing its ULTRA BLUE robotic truck-loading system. It needed machine components that could withstand continuous, high-cycle operation in dynamic, dust-prone environments.

The answer came in the form of high-performance, lubrication-free motion plastics from igus.

Here’s how the integration of polymer products — including plain bearings, linear guides, spherical ball joints, and slewing bearings — enabled Bastian Solutions to improve ULTRA BLUE’s efficiency and reliability while reducing costs.

Bastian builds ULTRA BLUE to improve warehousing safety

Bastian designed ULTRA BLUE to replace manual loading of boxes and cases into truck trailers. By automating these high-volume loading operations, this mobile system addresses the physical demands and safety risks associated with repetitive heavy lifting in warehouses and manufacturing facilities.

ULTRA BLUE can autonomously navigate between multiple dock doors without requiring rails, in-ground equipment, or other additional infrastructure. Its components include a retractable mast, custom end-of-arm tooling (EOAT) with six degrees of freedom and articulating conveyors.

The process works like this: Boxes travel from an extendable conveyor attached to the back of the system, then up the mast. From there, the EOAT precisely places the boxes inside the trailer from the ground up using lidar navigation.

ULTRA BLUE can handle over 1,000 cases per hour in 24/7 operations and requires only a single operator to manage an entire fleet through a centralized control interface.

Robot operates in demanding conditions

Unlike other automatic loading systems, ULTRA BLUE combines several capabilities into a single, efficient solution. Designing it, however, required bearings and other machine components that could handle the robot’s challenging operational environment. These conditions included:

- Temperature swings: From humidity in the summer to cold temperatures in the winter, temperature fluctuations can impact the performance and lifespan of traditional metal bearings, which require specialized lubricants that can degrade under such conditions.

- Dust and debris: The presence of particles and dust due to the corrugated boxes can lead to rapid wear and tear in traditional components, necessitating frequent costly maintenance and bearing replacement.

- Various box conditions: ULTRA BLUE must handle a variety of packages, such as thin, bowing or damaged boxes that are irregularly sealed and packaged, creating dynamic and potentially high-impact loads on the internal mechanisms and bearings.

To address these challenges, Bastian Solutions needed components that could survive the robot’s high cycle times and dusty environments for long periods of time. They also had to support heavy impact loads during operation.

igus provides lubrication-free solution

Instead of continuing to fight these maintenance battles, Bastian Solutions turned to igus for a robust and reliable solution, integrating a suite of the company’s high-performance polymer components into ULTRA BLUE. These included:

- Plain bearings were used in a four-bar linkage mechanism driven by a cam profile.

- Linear guides support the linkage mechanism. Larger custom guides were also added to the system’s conveyor section.

- Spherical ball joints connect two conveyor sections that pivot relative to each other.

- Plain slewing bearings were incorporated as a rear pivot of a conveyor section — an area that was prone to debris buildup.

The combination of these components addressed ULTRA BLUE’s operational challenges and performance requirements. For example, a key design feature across all igus components is their self-lubricating nature.

Unlike metal bearings that demand regular lubrication, igus bearings are made from high-performance plastics that contain solid lubricants embedded within the material, eliminating the need for external lubrication and delivering several key advantages:

Reduced maintenance costs and downtime. The self-lubricating nature of igus components reduces the labor, time and associated costs of routine maintenance. For ULTRA BLUE, the ability to operate across multiple shifts and reduce downtime is critical for maximizing warehousing productivity.

Contamination prevention. In environments with debris from corrugated boxes, lubricants can attract and trap particles, leading to premature wear and contamination. The use of igus bearings prevents these issues, ensuring cleaner operation and extending component life. This feature has been especially beneficial for the slewing bearing used in a section of ULTRA BLUE prone to debris buildup.

Suitability for harsh environments. The ability to operate reliably without external lubricants makes igus components suitable for environments with temperature fluctuations, including those in which ULTRA BLUE operates. In such conditions, traditional greases are prone to thickening, thinning or degradation.

Components to enhance warehousing robot durability, reduce costs

Beyond solving the maintenance problems, the igus components enabled Bastian Solutions to reduce costs in several ways:

- For the four-bar linkage mechanism, switching to igus bearings not only doubled the system’s life but also cut the component cost by half.

- The spherical ball joint replaced a more expensive bearing and eliminated the need for a dust boot, further simplifying design and lowering costs.

- The components reduced customer maintenance labor and spare part costs.

The igus components even improved ULTRA BLUE’s design flexibility and performance. For example, a key feature of the linear guides is smooth, quiet operation, making the system’s operation more efficient and less disruptive in busy warehousing environments.

Designed with precise tolerances, the spherical ball joints also promote reliable performance in dynamic applications, including the ULTRA BLUE, whose two conveyor sections must pivot relative to each other.

Learn more about lubrication-free bearings

By implementing lubrication-free plain bearings, linear guides, spherical ball joints, and slewing bearings, Bastian Solutions successfully met the operational and performance requirements for its ULTRA BLUE warehousing robot.

To learn more about how igus components can benefit your robotic application, visit: www.igus.com.

The post Warehousing robot maker turns to lubrication-free motion plastics appeared first on The Robot Report.